April 23, 2013

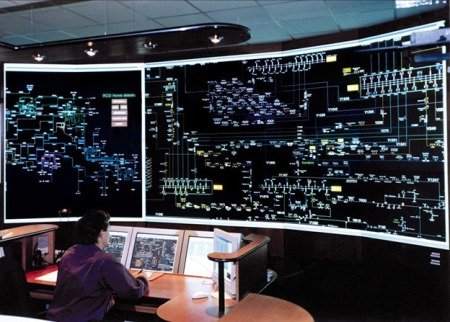

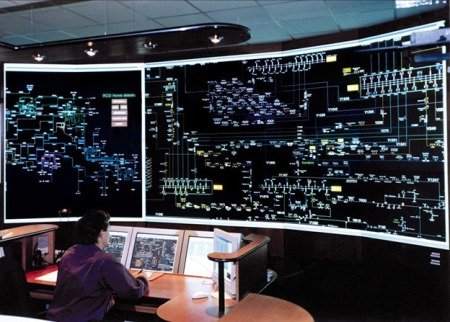

SCADA – The Heart Of Distribution Management System (DMS) – On photo: Fima UAB – Dedicated control systems and SCADA (Supervisory Control and Data Acquisition) as well as DMS (Distribution Management System) type of systems are offered for electricity, water and gas supply companies, as well as telecommunication operators and manufacturing companies.

SCADA System Elements

At a high level, the elements of a distribution automation system can be divided into three main areas:

- SCADA application and server(s)

- DMS applications and server(s)

- Trouble management applications and server(s)

Distribution SCADA

As was stated in the title, the Supervisory Control And Data Acquisition (SCADA) system is the heart of Distribution Management System (DMS) architecture.

A SCADA system should have all of the infrastructure elements to support the multifaceted nature of distribution automation and the higher level applications of a DMS. A Distribution SCADA system’s primary function is in support of distribution operations telemetry, alarming, event recording, and remote control of field equipment.

“Historically, SCADA systems have been notorious for their lack of support for the import, and more importantly, the export of power system data values.”

Baca entri selengkapnya »

Leave a Comment » |

Leave a Comment » |  Pengetahuan Umum |

Pengetahuan Umum |  Permalink

Permalink

Ditulis oleh yasilindo

Ditulis oleh yasilindo

April 23, 2013

Continued from technical article: Detecting Cyber Intrusion in SCADA System

Continued from technical article: Detecting Cyber Intrusion in SCADA System

The Three R’s As Response

The “three R’s” of the response to cyber intrusion are:

- Recording,

- Reporting, and

- Restoring.

Theoretically, it would be desirable to record all data communications into and out of all substation devices.

In that manner, if an intruder successfully attacks the system, the recordings could be used to determine what technique the intruder used, in order to modify the system and close that particular vulnerability. Secondly, the recording would be invaluable in trying to identify the intruder.

In addition, if the recording is made in a way that is demonstrably inalterable, then it may be admissible as evidence in court if the intruder is apprehended.

However, due to the high frequency of SCADA communications, the low cost of substation communications equipment, and the fact that the substations are distant from corporate security staff, it may be impractical to record all communications.

Baca entri selengkapnya »

Leave a Comment » |

Leave a Comment » |  Pengetahuan Umum |

Pengetahuan Umum |  Permalink

Permalink

Ditulis oleh yasilindo

Ditulis oleh yasilindo

April 23, 2013

How to recognize intrusion?

One of the axioms of cyber security is that although it is extremely important to try to prevent intrusions into one’s systems and databases, it is essential that intrusions be detected if they do occur.

An intruder who gains control of a substation computer can modify the computer code or insert a new program. The new software can be programmed to quietly gather data (possibly including the log-on passwords of legitimate users) and send the data to the intruder at a later time.

It can be programmed to operate power system devices at some future time or upon the recognition of a future event. It can set up a mechanism (sometimes called a ‘‘backdoor’’) that will allow the intruder to easily gain access at a future time.

Baca entri selengkapnya »

Leave a Comment » |

Leave a Comment » |  Pengetahuan Umum |

Pengetahuan Umum |  Permalink

Permalink

Ditulis oleh yasilindo

Ditulis oleh yasilindo

April 23, 2013

Operating Speed Range

The desired speed range may be difficult to achieve depending on the type of application. In general, depending on motor size and load type, very wide ranges may require a special motor.

Operation at very low speeds, requiring the motor to run at very low frequency (below approximately 6 Hz) or very high speeds requiring the motor to run at very high frequencies (above 90 Hz) may require a special motor.

Motor synchronous speed varies directly with the control output frequency. Therefore, the frequency required to achieve a desired application speed can be approximated by dividing the desired speed by the motor rated speed and then multiplying by the rated frequency of the motor.

Baca entri selengkapnya »

Leave a Comment » |

Leave a Comment » |  Teori |

Teori |  Permalink

Permalink

Ditulis oleh yasilindo

Ditulis oleh yasilindo

April 23, 2013

Introduction to torque

The rotating force that a motor develops is called torque.

Due to the physical laws of inertia, where a body at rest tends to remain at rest, the amount of torque necessary to start a load (starting torque) is always much greater than the amount of torque required to maintain rotation of the load after it has achieved normal speed.

The more quickly a load must accelerate from rest to normal rotational speed, the greater must be the torque capability of the motor driver.

“For very large inertia loads or loads that must be accelerated quickly, a motor having a high starting torque should be applied.”

The National Electrical Manufacturers Association (NEMA) provides design letters to indicate the torque, slip, and starting characteristics of three-phase induction motors.

Baca entri selengkapnya »

Leave a Comment » |

Leave a Comment » |  Teori |

Teori |  Permalink

Permalink

Ditulis oleh yasilindo

Ditulis oleh yasilindo

Mei 9, 2012

Machines that are subject to harsh or prolonged vibration present challenges for many components – none more so than position and speed sensors. This article lists 10 simple rules for design engineers when selecting position and speed sensors that must cope with shock or vibration.

There are many examples of harsh shock and vibration environments: off-road vehicles, airborne avionics and mining equipment. There are also some less obvious examples such as pumps and refrigeration plant, where the vibration is less extreme but persists over many years. Of course, characteristics will vary from application to application but generally all environments with vibration or shock can present significant problems for electrical control systems, particularly position and speed sensors.

Baca entri selengkapnya »

Leave a Comment » |

Leave a Comment » |  Pengetahuan Umum |

Pengetahuan Umum |  Permalink

Permalink

Ditulis oleh yasilindo

Ditulis oleh yasilindo

Mei 9, 2012

Under recent economic conditions, it is understandable that a control-system cyber-security audit is not the top priority for many plant operators. Less staff due to layoffs and deferred maintenance can present a clear, tangible threat to operations. Too often, “the imaginary hacker,” discussed in many papers and blogs, is often considered as a non-credible threat. No matter how many blogs, magazine articles and white papers are written, a real credible threat to a refinery or petrochemical facility from some vague person or organization seems “imaginary” to those controlling plant budgets.

Baca entri selengkapnya »

Leave a Comment » |

Leave a Comment » |  Pengetahuan Umum |

Pengetahuan Umum |  Permalink

Permalink

Ditulis oleh yasilindo

Ditulis oleh yasilindo

Mei 9, 2012

Enough has been written during the past couple years to convince most plant managers of the benefits of connecting plant floor equipment and processes to the Internet or Intranet. So, now that we’re all convinced of the benefits of web-enabled automation, what pieces and parts are required to put this technology to work? The basic parts required for web-based data acquisition and control are:

- an interface to the machine or process to be monitored or controlled via the web (network) connection;

- a web server to make the desired display and/or control pages available to the remote browser or client; and

- a data service or interface to handle exchanging data between the local machine/process (server) and the remote system (client).

Baca entri selengkapnya »

Leave a Comment » |

Leave a Comment » |  Pengetahuan Umum |

Pengetahuan Umum |  Permalink

Permalink

Ditulis oleh yasilindo

Ditulis oleh yasilindo

Agustus 13, 2009

In electronics, a switch is an electrical component that can break an electrical circuit, interrupting the current or diverting it from one conductor to another. The most familiar form of switch is a manually operated electromechanical device with one or more sets of electrical contacts. Each set of contacts can be in one of two states: either ‘closed’ meaning the contacts are touching and electricity can flow between them, or ‘open’, meaning the contacts are separated and nonconducting.

Baca entri selengkapnya »

Leave a Comment » |

Leave a Comment » |  Pengetahuan Umum |

Pengetahuan Umum |  Permalink

Permalink

Ditulis oleh yasilindo

Ditulis oleh yasilindo

Agustus 13, 2009

Variable-frequency drive

A variable-frequency drive (VFD) is a system for controlling the rotational speed of an alternating current (AC) electric motor by controlling the frequency of the electrical power supplied to the motor. A variable frequency drive is a specific type ofadjustable-speed drive. Variable-frequency drives are also known as adjustable-frequency drives (AFD), variable-speed drives (VSD), AC drives, microdrives or inverter drives. Since the voltage is varied along with frequency, these are sometimes also called VVVF (variable voltage variable frequency) drives.

A variable-frequency drive (VFD) is a system for controlling the rotational speed of an alternating current (AC) electric motor by controlling the frequency of the electrical power supplied to the motor. A variable frequency drive is a specific type ofadjustable-speed drive. Variable-frequency drives are also known as adjustable-frequency drives (AFD), variable-speed drives (VSD), AC drives, microdrives or inverter drives. Since the voltage is varied along with frequency, these are sometimes also called VVVF (variable voltage variable frequency) drives.

Variable-frequency drives are widely used. For example, in ventilations systems for large buildings, variable-frequency motors on fans save energy by allowing the volume of air moved to match the system demand. Variable frequency drives are also used on pumps, conveyor and machine tool drives.

Baca entri selengkapnya »

Leave a Comment » |

Leave a Comment » |  Pengetahuan Umum |

Pengetahuan Umum |  Permalink

Permalink

Ditulis oleh yasilindo

Ditulis oleh yasilindo

Agustus 13, 2009

Troubleshooting is a form of problem solving most often applied to repair of failed products or processes. It is a logical, systematic search for the source of a problem so that it can be solved, and so the product or process can be made operational again. Troubleshooting is needed to develop and maintain complex systems where the symptoms of a problem can have many possible causes. Troubleshooting is used in many fields such as engineering, system administration, electronics, automotive repair, and diagnostic medicine. Troubleshooting requires identification of the malfunction(s) or symptoms within a system. Then, experience is commonly used to generate possible causes of the symptoms. Determining which cause is most likely is often a process of elimination – eliminating potential causes of a problem. Finally, troubleshooting requires confirmation that the solution restores the product or process to its working state.

Baca entri selengkapnya »

Leave a Comment » |

Leave a Comment » |  Pengetahuan Umum |

Pengetahuan Umum |  Permalink

Permalink

Ditulis oleh yasilindo

Ditulis oleh yasilindo

Agustus 13, 2009

Water treatment describes those processes used to make water more acceptable for a desired end-use. These can include use as drinking water, industrial processes, medical and many other uses. The goal of all water treatment process is to remove existingcontaminants in the water, or reduce the concentration of such contaminants so the water becomes fit for its desired end-use. One such use is returning water that has been used back into the natural environment without adverse ecological impact.

Water treatment describes those processes used to make water more acceptable for a desired end-use. These can include use as drinking water, industrial processes, medical and many other uses. The goal of all water treatment process is to remove existingcontaminants in the water, or reduce the concentration of such contaminants so the water becomes fit for its desired end-use. One such use is returning water that has been used back into the natural environment without adverse ecological impact.

The processes involved in treating water for drinking purpose may be solids separation using physical such as settling and filtration,chemical such as disinfection and coagulation.

Biological processes are also employed in the treatment of wastewater and these processes may include, for example, aerated lagoons, activated sludge or slow sand filters.

Leave a Comment » |

Leave a Comment » |  Pengetahuan Umum |

Pengetahuan Umum |  Permalink

Permalink

Ditulis oleh yasilindo

Ditulis oleh yasilindo

Agustus 13, 2009

Electric light

Most of the industrialized world is lit by electric lights, which are used both at night and to provide additional light during the daytime. These lights are normally powered by the electric grid, but some run on local generators, and emergency generators serve as backups in hospitals and other locations where a loss of power could be catastrophic. Battery-powered lights, usually called “flashlights” or “torches”, are used for portability and as backups when the main lights fail.

Baca entri selengkapnya »

Leave a Comment » |

Leave a Comment » |  Pengetahuan Umum |

Pengetahuan Umum |  Permalink

Permalink

Ditulis oleh yasilindo

Ditulis oleh yasilindo

Agustus 4, 2009

A fire alarm control panel (FACP), or fire alarm control unit (FACU), is an electric panel that is the controlling component of a fire alarm system. The panel receives information from environmental sensors designed to detect changes associated with fire, monitors their operational integrity and provides for automatic control of equipment, and transmission of information necessary to prepare the facility for fire based on a predetermined sequence. The panel may also supply electrical energy to operate any associated sensor, control, transmitter, or relay. There are four basic types of panels: coded panels, conventional panels, addressable panels, and multiplex systems. A fire alarm control panel is required under the building code for a majority of new commercial building construction in most countries.

A fire alarm control panel (FACP), or fire alarm control unit (FACU), is an electric panel that is the controlling component of a fire alarm system. The panel receives information from environmental sensors designed to detect changes associated with fire, monitors their operational integrity and provides for automatic control of equipment, and transmission of information necessary to prepare the facility for fire based on a predetermined sequence. The panel may also supply electrical energy to operate any associated sensor, control, transmitter, or relay. There are four basic types of panels: coded panels, conventional panels, addressable panels, and multiplex systems. A fire alarm control panel is required under the building code for a majority of new commercial building construction in most countries.

Baca entri selengkapnya »

Leave a Comment » |

Leave a Comment » |  Pengetahuan Umum |

Pengetahuan Umum |  Permalink

Permalink

Ditulis oleh yasilindo

Ditulis oleh yasilindo

Agustus 4, 2009

An automatic fire alarm system is designed to detect the unwanted presence of fire by monitoring environmental changes associated with combustion. In general, a fire alarm system is either classified as automatic, manually activated, or both. Automatic fire alarm systems can be used to notify people to evacuate in the event of a fire or other emergency, to summon emergency forces aid, and to prepare the structure and associated systems to control the spread of fire and smoke.

An automatic fire alarm system is designed to detect the unwanted presence of fire by monitoring environmental changes associated with combustion. In general, a fire alarm system is either classified as automatic, manually activated, or both. Automatic fire alarm systems can be used to notify people to evacuate in the event of a fire or other emergency, to summon emergency forces aid, and to prepare the structure and associated systems to control the spread of fire and smoke.

Design

After the fire protection goals are established – usually by referencing the minimum levels of protection mandated by the appropriate model building code, insurance agencies, and other authorities – the fire alarm designer undertakes to detail specific components, arrangements, and interfaces necessary to accomplish these goals. Equipment specifically manufactured for these purposes are selected and standardized installation methods are anticipated during the design. In the United States, NFPA 72, The National Fire Alarm Code is an established and widely used installation standard.

Baca entri selengkapnya »

Leave a Comment » |

Leave a Comment » |  Pengetahuan Umum |

Pengetahuan Umum |  Permalink

Permalink

Ditulis oleh yasilindo

Ditulis oleh yasilindo

Juli 31, 2009

Automation is the use of control systems (such as numerical control, programmable logic control, and other industrial control systems), in concert with other applications of information technology (such as computer-aided technologies [CAD, CAM, CAx]), to control industrial machinery and processes, reducing the need for human intervention. In the scope of industrialization, automation is a step beyond mechanization. Whereas mechanization provided human operators with machinery to assist them with the physical requirements of work, automation greatly reduces the need for human sensory and mental requirements as well. Processes and systems can also be automated. Automation plays an increasingly important role in the global economy and in daily experience. Engineers strive to combine automated devices with mathematical and organizational tools to create complex systems for a rapidly expanding range of applications and human activities. Many roles for humans in industrial processes presently lie beyond the scope of automation. Human-level pattern recognition, language recognition, and language production ability are well beyond the capabilities of modern mechanical and computer systems. Tasks requiring subjective assessment or synthesis of complex sensory data, such as scents and sounds, as well as high-level tasks such as strategic planning, currently require human expertise. In many cases, the use of humans is more cost-effective than mechanical approaches even where automation of industrial tasks is possible. Specialised hardened computers, referred to as programmable logic controllers (PLCs), are frequently used to synchronize the flow of inputs from (physical) sensors and events with the flow of outputs to actuators and events. This leads to precisely controlled actions that permit a tight control of almost any industrial process. Human-machine interfaces (HMI) or computer human interfaces (CHI), formerly known as man-machine interfaces, are usually employed to communicate with PLCs and other computers, such as entering and monitoring temperatures or pressures for further automated control or emergency response. Service personnel who monitor and control these interfaces are often referred to as stationary engineers.

Automation is the use of control systems (such as numerical control, programmable logic control, and other industrial control systems), in concert with other applications of information technology (such as computer-aided technologies [CAD, CAM, CAx]), to control industrial machinery and processes, reducing the need for human intervention. In the scope of industrialization, automation is a step beyond mechanization. Whereas mechanization provided human operators with machinery to assist them with the physical requirements of work, automation greatly reduces the need for human sensory and mental requirements as well. Processes and systems can also be automated. Automation plays an increasingly important role in the global economy and in daily experience. Engineers strive to combine automated devices with mathematical and organizational tools to create complex systems for a rapidly expanding range of applications and human activities. Many roles for humans in industrial processes presently lie beyond the scope of automation. Human-level pattern recognition, language recognition, and language production ability are well beyond the capabilities of modern mechanical and computer systems. Tasks requiring subjective assessment or synthesis of complex sensory data, such as scents and sounds, as well as high-level tasks such as strategic planning, currently require human expertise. In many cases, the use of humans is more cost-effective than mechanical approaches even where automation of industrial tasks is possible. Specialised hardened computers, referred to as programmable logic controllers (PLCs), are frequently used to synchronize the flow of inputs from (physical) sensors and events with the flow of outputs to actuators and events. This leads to precisely controlled actions that permit a tight control of almost any industrial process. Human-machine interfaces (HMI) or computer human interfaces (CHI), formerly known as man-machine interfaces, are usually employed to communicate with PLCs and other computers, such as entering and monitoring temperatures or pressures for further automated control or emergency response. Service personnel who monitor and control these interfaces are often referred to as stationary engineers.

Baca entri selengkapnya »

Leave a Comment » |

Leave a Comment » |  Pengetahuan Umum |

Pengetahuan Umum |  Permalink

Permalink

Ditulis oleh yasilindo

Ditulis oleh yasilindo

Juli 25, 2009

Building automation describes the functionality provided by the control system of a building. A building automation system (BAS) is an example of a distributed control system. The control system is a computerized, intelligent network of electronic devices, designed to monitor and control the mechanical and lighting systems in a building.

BAS core functionality keeps the building climate within a specified range, provides lighting based on an occupancy schedule, and monitors system performance and device failures and provides email and/or text notifications to building engineering staff. The BAS functionality reduces building energy and maintenance costs when compared to a non-controlled building. A building controlled by a BAS is often referred to as an intelligent building system.

Baca entri selengkapnya »

Leave a Comment » |

Leave a Comment » |  Pengetahuan Umum |

Pengetahuan Umum |  Permalink

Permalink

Ditulis oleh yasilindo

Ditulis oleh yasilindo

Juli 9, 2009

An electrical drawing, a type of technical drawing, shows information about power, lighting, and communication for an engineering or architectural project. Any electrical working drawing consists of “lines, symbols, dimensions, and notations to accurately convey an engineering’s design to the workers, who install the electrical system on the job”.

A complete set of working drawings for the average electrical system in large projects usually consists of:

- A plot plan showing the building’s location and outside electrical wiring

- Floor plans showing the location of electrical systems on every floor

- Power-riser diagrams showing panel boards

- Control wiring schemes

- Schedules and other information in combination with construction drawings.

Electrical drafters prepare wiring and layout diagrams used by workers who erect, install, and repair electrical equipment and wiring in communication centers, power plants, electrical distribution systems, and buildings.

Baca entri selengkapnya »

Leave a Comment » |

Leave a Comment » |  Pengetahuan Umum |

Pengetahuan Umum |  Permalink

Permalink

Ditulis oleh yasilindo

Ditulis oleh yasilindo

Juli 9, 2009

SCADA stands for Supervisory Control And Data Acquisition. It generally refers to an industrial control system: a computer system monitoring and controlling a process. The process can be industrial, infrastructure or facility based as described below:

- Industrial processes include those of manufacturing, production, power generation, fabrication, and refining, and may run in continuous, batch, repetitive, or discrete modes.

- Infrastructure processes may be public or private, and include water treatment and distribution, wastewater collection and treatment, oil and gas pipelines, electrical power transmission and distribution, civil defense siren systems, and large communication systems.

- Facility processes occur both in public facilities and private ones, including buildings, airports, ships, and space stations. They monitor and control HVAC, access, and energy consumption.

A SCADA System usually consists of the following subsystems:

There is, in several industries, considerable confusion over the differences between SCADA systems and Distributed control systems (DCS). Generally speaking, a SCADA system usually refers to a system that coordinates, but does not control processes in real time. The discussion on real-time control is muddied somewhat by newer telecommunications technology, enabling reliable, low latency, high speed communications over wide areas. Most differences between SCADA and DCS are culturally determined and can usually be ignored. As communication infrastructures with higher capacity become available, the difference between SCADA and DCS will fade.

Baca entri selengkapnya »

Leave a Comment » |

Leave a Comment » |  Pengetahuan Umum |

Pengetahuan Umum |  Permalink

Permalink

Ditulis oleh yasilindo

Ditulis oleh yasilindo

Juli 9, 2009

The user interface (also known as human computer interface or man-machine interface (MMI)) is the aggregate of means by which people—the users—interact with the system—a particular machine, device, computer program or other complex tool. The user interface provides means of:

- Input, allowing the users to manipulate a system

- Output, allowing the system to indicate the effects of the users’ manipulation.

Baca entri selengkapnya »

Leave a Comment » |

Leave a Comment » |  Pengetahuan Umum |

Pengetahuan Umum |  Permalink

Permalink

Ditulis oleh yasilindo

Ditulis oleh yasilindo

Juli 9, 2009

A programmable logic controller (PLC) or programmable controller is a digital computer used for automation of electromechanical processes, such as control of machinery on factory assembly lines, amusement rides, or lighting fixtures. PLCs are used in many industries and machines, such as packaging and semiconductor machines. Unlike general-purpose computers, the PLC is designed for multiple inputs and output arrangements, extended temperature ranges, immunity to electrical noise, and resistance to vibration and impact. Programs to control machine operation are typically stored in battery-backed or non-volatile memory. A PLC is an example of a real time system since output results must be produced in response to input conditions within a bounded time, otherwise unintended operation will result.

Baca entri selengkapnya »

Leave a Comment » |

Leave a Comment » |  Pengetahuan Umum |

Pengetahuan Umum |  Permalink

Permalink

Ditulis oleh yasilindo

Ditulis oleh yasilindo

Juli 9, 2009

A motor controller is a device or group of devices that serves to govern in some predetermined manner the performance of an electric motor. A motor controller might include a manual or automatic means for starting and stopping the motor, selecting forward or reverse rotation, selecting and regulating the speed, regulating or limiting the torque, and protecting against overloads and faults.

Baca entri selengkapnya »

Leave a Comment » |

Leave a Comment » |  Pengetahuan Umum |

Pengetahuan Umum |  Permalink

Permalink

Ditulis oleh yasilindo

Ditulis oleh yasilindo

Juli 9, 2009

An electric switchboard is a device that directs electricity from one source to another. It is an assembly of panels, each of which contain switches that allow electricity to be redirected. The operator is protected from electrocution by safety switches and fuses.

An electric switchboard is a device that directs electricity from one source to another. It is an assembly of panels, each of which contain switches that allow electricity to be redirected. The operator is protected from electrocution by safety switches and fuses.

There can also be controls for the supply of electricity to the switchboard, coming from a generator or bank of electrical generators, especially frequency control of AC power and load sharing controls, plus gauges showing frequency and perhaps a synchroscope. The amount of power going into a switchboard must always equal to the power going out to the loads.

Inside the switchboard there is a bank of busbars – generally wide strips of copper to which the switchgear is connected. These act to allow the flow of large currents through the switchboard, and are generally bare and supported by insulators. Power to a switchboard should first be isolated before a switchboard is opened for maintenance, as the bare Busbars represent a severe electrocution hazard. Working on a live switchboard is rarely necessary, and if it is done then precautions should be taken, such as standing on a thick rubber mat, the use of gloves etc.

Baca entri selengkapnya »

Leave a Comment » |

Leave a Comment » |  Pengetahuan Umum |

Pengetahuan Umum |  Permalink

Permalink

Ditulis oleh yasilindo

Ditulis oleh yasilindo

Juli 9, 2009

Electrical engineering, sometimes referred to as electrical and electronic engineering, is a field of engineering that deals with the study and application of electricity, electronics and electromagnetism. The field first became an identifiable occupation in the late nineteenth century after commercialization of the electric telegraph and electrical power supply. It now covers a range of subtopics including power, electronics, control systems, signal processing and telecommunications.

Baca entri selengkapnya »

Leave a Comment » |

Leave a Comment » |  Pengetahuan Umum |

Pengetahuan Umum |  Permalink

Permalink

Ditulis oleh yasilindo

Ditulis oleh yasilindo

Ditulis oleh yasilindo

Ditulis oleh yasilindo

A conveyor system is a common piece of mechanical handling equipment that moves materials from one location to another. Conveyors are especially useful in applications involving the transportation of heavy or bulky materials. Conveyor systems allow quick and efficient transportation for a wide variety of materials, which make them very popular in the

A conveyor system is a common piece of mechanical handling equipment that moves materials from one location to another. Conveyors are especially useful in applications involving the transportation of heavy or bulky materials. Conveyor systems allow quick and efficient transportation for a wide variety of materials, which make them very popular in the  An electric motor is a device using

An electric motor is a device using  A variable-frequency drive (VFD) is a system for controlling the rotational speed of an

A variable-frequency drive (VFD) is a system for controlling the rotational speed of an  A cable is two or more

A cable is two or more  A circuit breaker is an automatically-operated

A circuit breaker is an automatically-operated  Water treatment describes those processes used to make

Water treatment describes those processes used to make  Motor starting auto transformers for on-line starting of motors are simple and economical. Offering maximum starting acceleration and torque. auto transformer overcomes the two major limitations of on-line starters – high starting current and high starting torque.

Motor starting auto transformers for on-line starting of motors are simple and economical. Offering maximum starting acceleration and torque. auto transformer overcomes the two major limitations of on-line starters – high starting current and high starting torque. A fire alarm control panel (FACP), or fire alarm control unit (FACU), is an electric panel that is the controlling component of a

A fire alarm control panel (FACP), or fire alarm control unit (FACU), is an electric panel that is the controlling component of a  An automatic fire alarm system is designed to detect the unwanted presence of

An automatic fire alarm system is designed to detect the unwanted presence of  Automation is the use of control systems (such as numerical control, programmable logic control, and other industrial control systems), in concert with other applications of information technology (such as computer-aided technologies [CAD, CAM, CAx]), to control industrial machinery and processes, reducing the need for human intervention. In the scope of industrialization, automation is a step beyond mechanization. Whereas mechanization provided human operators with machinery to assist them with the physical requirements of work, automation greatly reduces the need for human sensory and mental requirements as well. Processes and systems can also be automated. Automation plays an increasingly important role in the global economy and in daily experience. Engineers strive to combine automated devices with mathematical and organizational tools to create complex systems for a rapidly expanding range of applications and human activities. Many roles for humans in industrial processes presently lie beyond the scope of automation. Human-level pattern recognition, language recognition, and language production ability are well beyond the capabilities of modern mechanical and computer systems. Tasks requiring subjective assessment or synthesis of complex sensory data, such as scents and sounds, as well as high-level tasks such as strategic planning, currently require human expertise. In many cases, the use of humans is more cost-effective than mechanical approaches even where automation of industrial tasks is possible. Specialised hardened computers, referred to as programmable logic controllers (PLCs), are frequently used to synchronize the flow of inputs from (physical) sensors and events with the flow of outputs to actuators and events. This leads to precisely controlled actions that permit a tight control of almost any industrial process. Human-machine interfaces (HMI) or computer human interfaces (CHI), formerly known as man-machine interfaces, are usually employed to communicate with PLCs and other computers, such as entering and monitoring temperatures or pressures for further automated control or emergency response. Service personnel who monitor and control these interfaces are often referred to as stationary engineers.

Automation is the use of control systems (such as numerical control, programmable logic control, and other industrial control systems), in concert with other applications of information technology (such as computer-aided technologies [CAD, CAM, CAx]), to control industrial machinery and processes, reducing the need for human intervention. In the scope of industrialization, automation is a step beyond mechanization. Whereas mechanization provided human operators with machinery to assist them with the physical requirements of work, automation greatly reduces the need for human sensory and mental requirements as well. Processes and systems can also be automated. Automation plays an increasingly important role in the global economy and in daily experience. Engineers strive to combine automated devices with mathematical and organizational tools to create complex systems for a rapidly expanding range of applications and human activities. Many roles for humans in industrial processes presently lie beyond the scope of automation. Human-level pattern recognition, language recognition, and language production ability are well beyond the capabilities of modern mechanical and computer systems. Tasks requiring subjective assessment or synthesis of complex sensory data, such as scents and sounds, as well as high-level tasks such as strategic planning, currently require human expertise. In many cases, the use of humans is more cost-effective than mechanical approaches even where automation of industrial tasks is possible. Specialised hardened computers, referred to as programmable logic controllers (PLCs), are frequently used to synchronize the flow of inputs from (physical) sensors and events with the flow of outputs to actuators and events. This leads to precisely controlled actions that permit a tight control of almost any industrial process. Human-machine interfaces (HMI) or computer human interfaces (CHI), formerly known as man-machine interfaces, are usually employed to communicate with PLCs and other computers, such as entering and monitoring temperatures or pressures for further automated control or emergency response. Service personnel who monitor and control these interfaces are often referred to as stationary engineers. In

In  An electric switchboard is a device that directs

An electric switchboard is a device that directs